16-12-2025

Metamerism: what It is and how It affects Color Control

In the field of industrial colorimetry, metamerism represents one of the most insidious challenges for quality control. This phenomenon can compromise the chromatic uniformity of products that appear to match perfectly during production but reveal clear differences when observed under different conditions.

Understanding metamerism is essential to ensure color consistency in sectors such as textiles, automotive, coatings, and plastics.

What is meant by Metamerism?

The term metameric derives from Greek and indicates a particular condition of apparent color matching.

Metamerism is the optical phenomenon whereby two color samples appear identical when illuminated by a specific light source but show clear differences when the lighting condition changes.

This discrepancy occurs even though the two samples have different spectral reflectance curves, meaning they reflect light differently across the visible spectrum.

The meaning of metamerism therefore goes beyond simple color perception: it is an intrinsic characteristic of colored materials that derives from their physical and chemical composition.

Two objects can be defined as metameric when their spectral “fingerprints” intersect at least at three points, creating a visual match under certain conditions but not under others.

In industrial practice, color metamerism becomes particularly critical when assembling components sourced from different suppliers or made from different materials.

A classic example is the automotive industry, where the painted bodywork must match chromatically with plastic bumpers and textile interiors, even though these elements use completely different pigments and coloring processes.

The causes of Metamerism

The causes of metamerism are multiple and interconnected, making this phenomenon particularly complex to manage. Understanding the triggering factors is the first step toward implementing effective control strategies.

The primary cause of metamerism lies in the nature of the light source. Each illuminant has a characteristic spectral distribution: incandescent light, for example, has high energy in the red region and a lower blue component, while daylight has a peak in the blue part of the spectrum. This difference determines how objects reflect light and, consequently, how they are perceived by the human eye.

A second determining factor is the composition of the pigments used. Different materials can produce the same chromatic effect under a specific illumination while having different molecular structures. When these materials are combined in a single product, the risk of metameric pairs is created.

Substances that contain fluorescent optical brighteners are particularly problematic, as they absorb ultraviolet light and re-emit it at visible wavelengths, significantly altering color perception.

Metamerism can manifest itself in several specific forms:

- Illuminant metamerism: occurs when two samples match under one light source but differ under another,

- Observer metamerism: emerges when two individuals perceive the same color pair differently due to variations in ocular photoreceptor sensitivity,

- Geometric metamerism: occurs when the viewing angle influences color perception, a phenomenon common with metallic, pearlescent, or specially textured materials.

Variations in dyeing processes, differences between production batches, and material aging can further amplify metamerism, making continuous monitoring throughout the entire production cycle necessary.

How to check and test Metamerism

Evaluating metamerism requires a methodical approach that combines visual and instrumental analysis. Integrating these two methods ensures accurate results and informed quality control decisions.

Visual analysis represents the first level of verification and requires the use of professional light booths. These devices allow samples to be observed under different standardized light sources, simulating real conditions of use. The booths must comply with international standards such as ISO 3664, ASTM D1729, and DIN 6173-2, which define controlled lighting parameters.

During the visual test, samples are compared under the primary illuminant and subsequently under at least two other light sources. If color matching is maintained under all conditions, the samples are not metameric; if differences emerge, the presence of metamerism is confirmed.

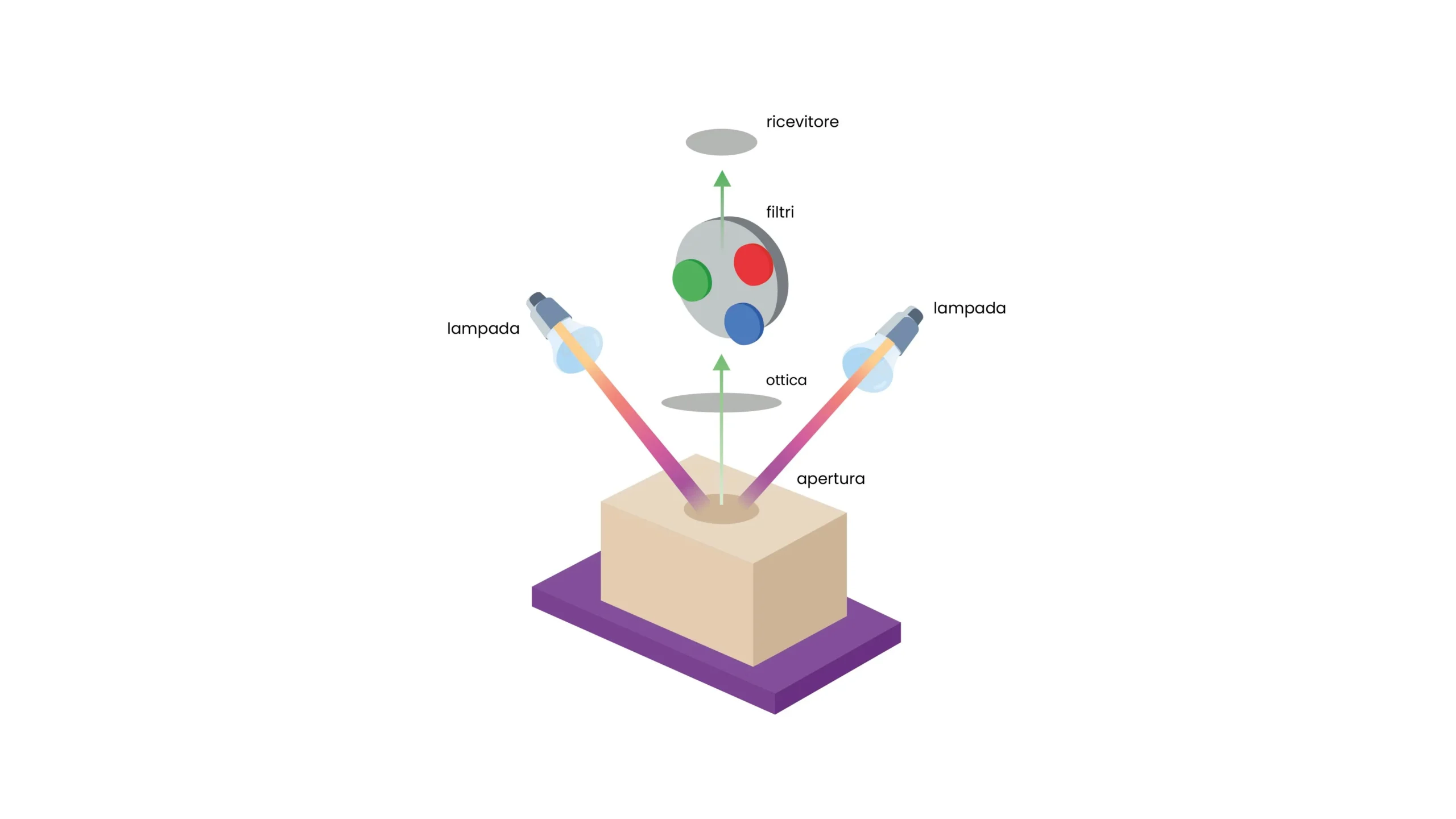

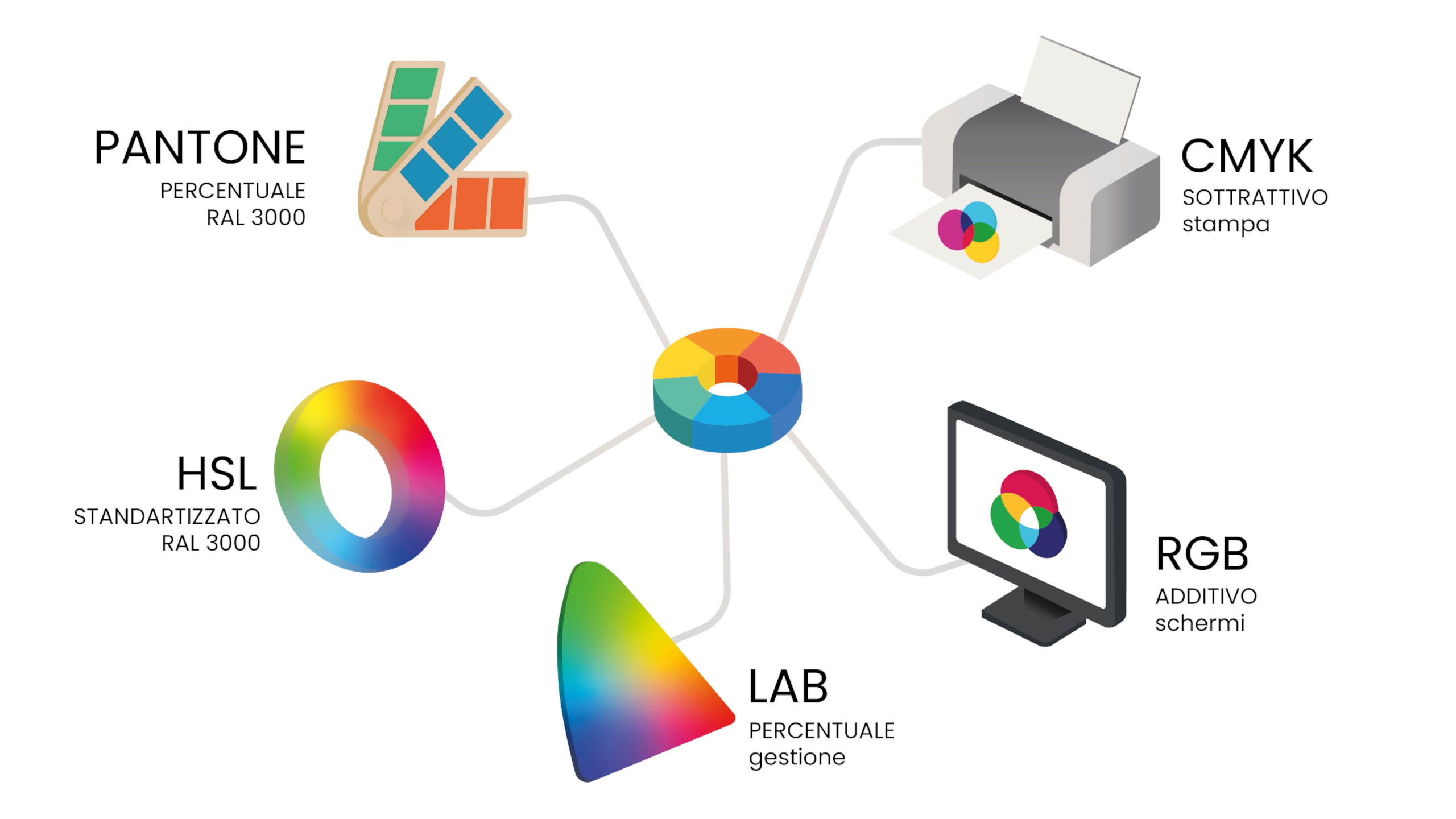

Instrumental evaluation provides precise and reproducible quantitative data. Professional spectrophotometers measure the spectral reflectance of samples across the entire visible spectrum, generating curves that represent the “fingerprint” of each color. Analyzing these curves makes it possible to identify metameric pairs even before production.

ColorWorkDesk offers complete solutions for metamerism control:

- Precision spectrophotometers: portable and benchtop devices that measure spectral reflectance with high accuracy, allowing the acquisition and comparison of color fingerprints,

- Professional light booths: standardized lighting systems with multiple light sources for visual evaluation under controlled conditions,

- Colorimetric analysis software: tools that automatically calculate metamerism indices and provide predictive analyses of chromatic performance.

The combination of these tools makes it possible to implement standard operating procedures that define acceptable tolerances and pass/fail criteria, which are essential for maintaining quality consistency throughout the supply chain.

To quantify the degree of metamerism, several mathematical indices are used. The CIE special metamerism index measures color difference under a test illuminant, while the DIN 6172 index corrects values to ensure an exact match with the primary illuminant.

The RMS (Root Mean Square) value calculates the square root of the squared chromatic differences across various combinations of illuminant and observer, providing an overall indication of chromatic stability.

Which Colors are Metameric?

Not all colors have the same likelihood of generating metameric pairs. Understanding which hues are more susceptible to this phenomenon makes it possible to adopt targeted preventive strategies.

The colors that show the greatest tendency toward metamerism are those characterized by low saturation and neutral tones.

Grays, in particular, represent the most problematic category, as they can be obtained through multiple pigment combinations with very different reflectance curves. Whites and pastel colors, especially when they contain optical brighteners, also show high sensitivity to lighting variations.

Dark colors, such as black and dark blue, are frequently subject to metamerism. A classic case is that of socks that appear both black under household lighting but reveal different shades in daylight.

In the textile sector, acrylic yarns naturally tend toward metamerism due to their synthetic nature, often shifting toward reddish tones under D65 illuminant.

By contrast, highly saturated and bright colors present a narrower range of possible metameric matches. This is because their spectral composition is more defined and leaves less room for alternative pigment combinations that produce the same visual effect.

Surface finishes significantly influence metameric behavior. Metallic, pearlescent, and special-effect materials show pronounced geometric metamerism, where the viewing angle becomes the critical factor.

Fabrics with special weaves, carpets, and embossed materials can exhibit significant chromatic variations depending on the viewing direction.

It is important to emphasize that chromatic metamerism is not a defect of the material itself, but a physical characteristic linked to the interaction between pigment composition, light source, and the human visual system.

In some sectors, such as textiles and fashion, controlled metameric effects are intentionally created to achieve iridescent and dynamic finishes that add aesthetic value to the product.

Metamerism FAQ

What Is the Difference Between Metamerism and Color Inconstancy?

Metamerism and color inconstancy are two distinct phenomena that are often confused but relate to different aspects of color perception.

For the definition of metamerism, please refer to the first paragraph.

Color inconstancy, on the other hand, concerns a single sample that changes its chromatic appearance as the illumination varies. In this case, there is no comparison between different objects: it is the same color that appears different in different lighting environments. A red fabric, for example, may appear duller under incandescent light and brighter in daylight, even though it is the same material.

The practical distinction is fundamental: while metamerism requires material formulation and matching strategies, color inconstancy is mainly managed through careful pigment selection and by anticipating chromatic behavior under the various intended conditions of use.

What Is the Difference Between Metamerism and Color Perception?

Color perception is the process through which the human visual system processes light stimuli and translates them into chromatic sensations. It is a complex phenomenon involving physical, physiological, and neurological aspects.

Metamerism is instead a specific and particular case of color perception. While general color perception describes how we see colors under normal conditions, metamerism highlights the limits of the human visual system.

Our eyes have three types of photosensitive cones that respond to different wavelengths (red, green, blue), but this trichromacy means that infinite spectral combinations can produce the same perceptual response.

Metamerism therefore exploits this characteristic of the visual system: two objects with different spectral fingerprints can stimulate the three types of cones identically under a specific illumination, generating the same color perception.

When the illumination changes, the cone responses change differently for the two objects, revealing their actual spectral diversity.

What Is Meant by Chromatic Metamerism?

The term chromatic metamerism is essentially synonymous with metamerism and is used to emphasize that the phenomenon specifically concerns color perception rather than other optical properties. Some professionals prefer this designation to distinguish it from other types of metameric correspondences in scientific contexts.

Chromatic metamerism highlights that the apparent match between two colors is limited to specific observation conditions. This specification is particularly relevant in industrial contexts where terminological precision is essential to define quality standards and tolerances.

In the technical language of colorimetry, when metamerism is mentioned it always refers to the chromatic phenomenon, making the adjective “chromatic” redundant but useful in educational contexts or when communicating with non-specialist audiences.

What Is Meant by Geometric Metamerism?

Geometric metamerism represents a particular manifestation of the metameric phenomenon linked to the viewing angle of the sample. Unlike illuminant metamerism, where the critical variable is the light source, in this case it is the observation geometry that determines perceptual differences.

This effect typically occurs with materials that exhibit anisotropic optical properties, meaning they interact with light differently depending on direction.

Metallic and pearlescent coatings are classic examples: metallic particles or effect pigments preferentially reflect light in certain directions, creating chromatic variations when the observer or the light source moves.

In the textile sector, geometric metamerism is often intentionally created through special weaves that reflect light directionally. Jacquard fabrics, velvets, and materials with specific finishes exploit this effect to achieve iridescent finishes that change hue depending on the viewing angle, adding dynamism and aesthetic value to the product.

The evaluation of geometric metamerism requires specific measurement protocols that consider multiple illumination and observation geometries.

Professional spectrophotometers can be configured with different geometric setups (such as 45°/0° or d/8°) to fully characterize the chromatic behavior of special-effect materials.

Subscribe to newsletter

Ask for a free consultation

Our experts will contact you to show you a demo of our products