12-09-2025

Light Booths: the fundamental tool for Color Quality Control

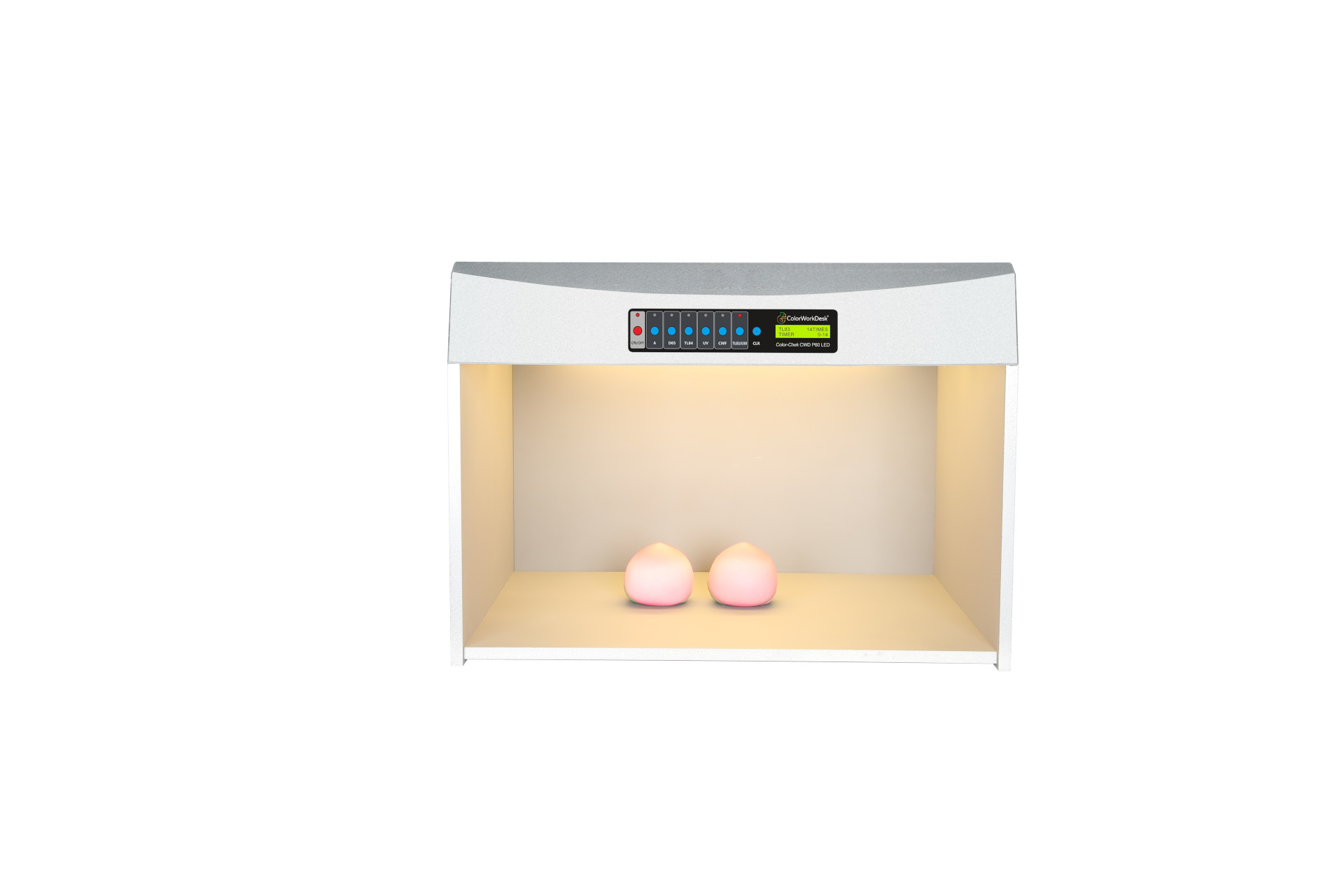

Light booths, also known as illumination booths or color viewing cabinets, are an essential tool in quality control laboratories and industries where accurate color evaluation is of critical importance. These specialized devices ensure standardized and controlled lighting conditions, eliminating environmental variables that can compromise color perception.

What Light Booths are used for: the color evaluation

The main purpose of light booths is to provide a standardized evaluation environment for color quality control. Color perception depends on numerous factors, including the type of lighting, light intensity, and surrounding environmental conditions. A light booth eliminates these variables, creating repeatable and comparable conditions.

Key applications include:

- Textile quality control: evaluation of fabrics, yarns, and garments to verify color consistency across different batches,

- Automotive industry: monitoring color uniformity of plastic components, paints, and coatings,

- Food sector: evaluation of the visual appearance of packaging, labels, and food products,

- Cosmetics industry: quality control of makeup products, assessing color rendering under different lighting conditions,

- Publishing and printing: evaluation of print proofs and color accuracy in graphic reproduction.

The use of standardized light booths also enables effective communication with suppliers and customers, providing a common reference for color evaluation that eliminates subjectivity and misunderstandings.

A crucial aspect is the prevention of metamerism, a phenomenon where two samples may appear identical under one light source but different under another.

Light booths are able to prevent metamerism and thus help create high-quality products, ensuring color consistency across different lighting conditions.

How a Light Booth works: structure and technical features

A light booth consists of a five-sided enclosed structure, with a front opening that allows samples to be inserted for evaluation. The interior is coated with a neutral medium gray material (Neutral Grey 7 according to international standards), ensuring maximum chromatic neutrality and minimizing unwanted reflections.

The key technical elements are:

- LED lighting system: modern booths use LED technology, which offers higher energy efficiency, longer lifespan, and color stability compared to traditional fluorescent lamps. LED systems provide instant ignition and an optimal stability indicator,

- Electronic control: dedicated microprocessors manage ignition, light intensity adjustment, and performance monitoring. Integrated LCD displays show the operating time of each light source, making maintenance scheduling easier,

- Viewing surface: flat and inclinable, made of neutral material so as not to interfere with color perception.

The size of the booths varies depending on the application. Compact models, such as desktop units, have external dimensions of approximately 663×492×358mm with internal dimensions of 693×550×501mm, while larger versions can reach 1317×802×590mm to accommodate larger samples.

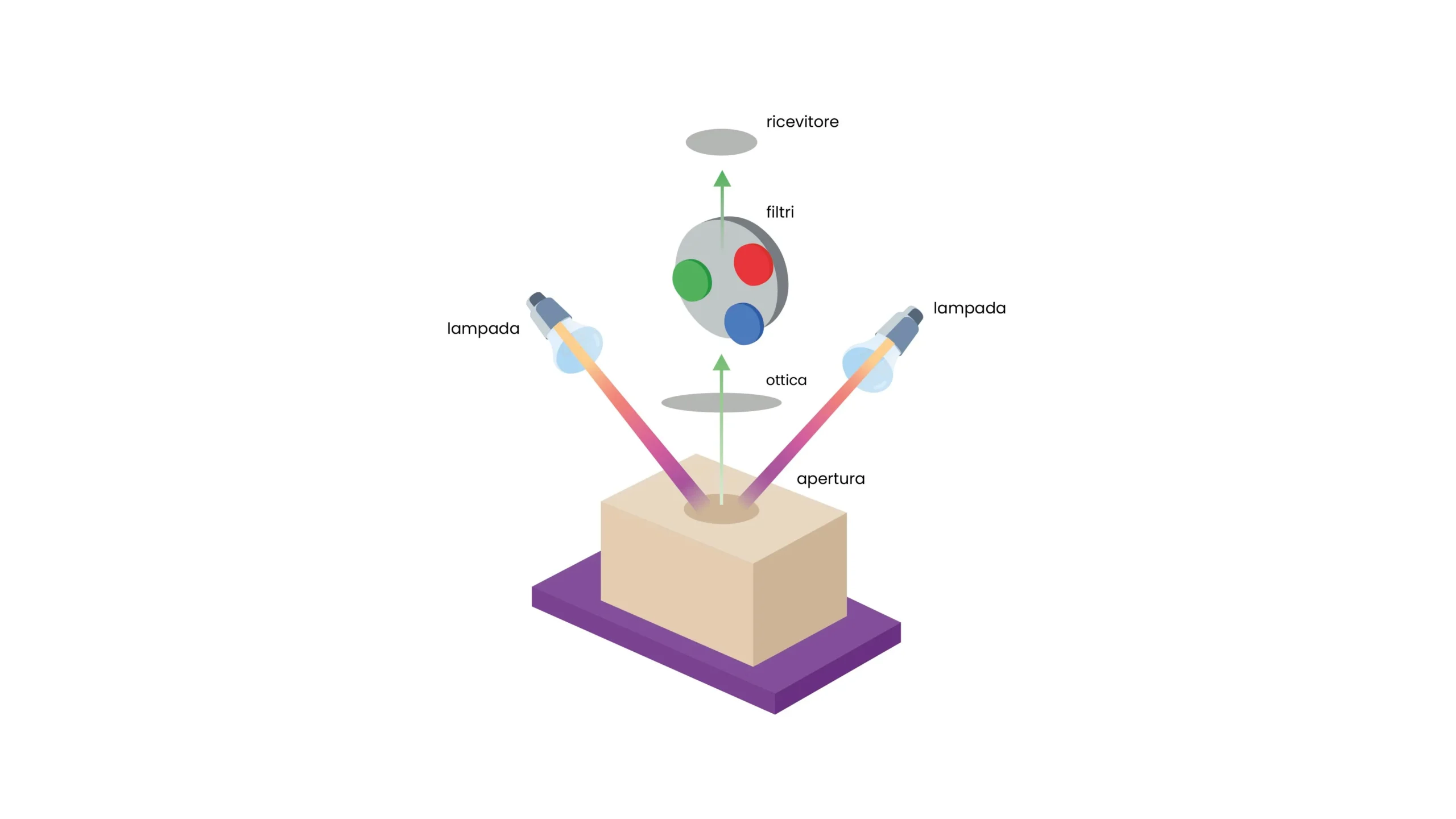

Standardized light sources: the core of evaluation

The added value of a professional light booth lies in its ability to faithfully reproduce different standardized lighting conditions. Each light source simulates specific environmental conditions and finds application in different sectors.

The main available light sources include:

- D65 (6500K): represents the international standard artificial daylight, used as the main reference for most color evaluations,

- TL84 (4000K): simulates typical store lighting in Europe, Japan, and China, essential for the retail sector,

- CWF (4150K): reproduces cool white fluorescent light according to American standards,

- F (2700K): mimics yellow sunset light and domestic incandescent lighting,

- TL83 (3000K): simulates warm white fluorescent light according to European standards,

- UV (365nm): ultraviolet light for detecting optical brighteners and fluorescent pigments.

The ability to compare samples under different light sources is essential to identify metamerism, i.e., the variation in color perception when lighting conditions change. The stability of light sources provides excellent viewing conditions for reliable quality control decisions, ensuring repeatable results over time.

Many disputes arise from the lack of shared tools within the supply chain, where lighting standards are not adequately specified (e.g., store lights, different materials, or color chemistry).

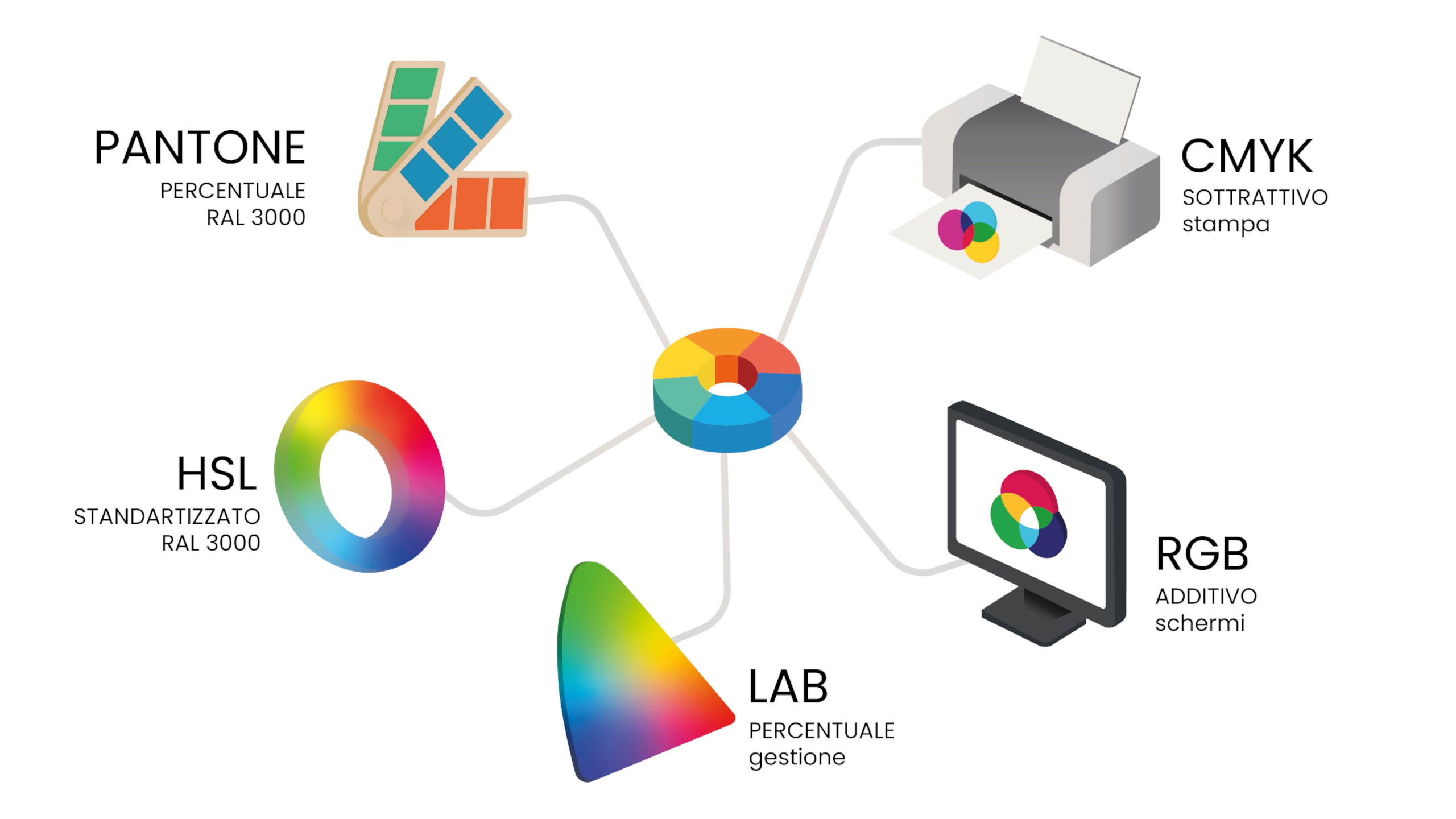

Metamerism control and measurement reliability

Metamerism control is one of the most critical aspects of industrial color evaluation. Two materials that appear identical under D65 lighting may show significant differences when observed under TL84 or domestic lighting.

This variability can cause major quality issues, especially in sectors such as textiles and automotive, where different components must maintain color uniformity.

Modern light booths address this challenge through:

- Standardized evaluation sequences: protocols requiring sample observation under all relevant light sources for the specific application,

- Stability control: continuous monitoring of the spectral characteristics of each source to ensure consistent performance,

- Data recording: tracking systems that document the conditions of each evaluation for process traceability.

Types of Light Booths and application differences

Light booths differ mainly in size, light source configuration, and construction features, allowing users to select the most suitable solution for specific application needs. Common types include:

- Compact desktop booths: ideal for laboratories with limited space and for evaluating small samples. They usually integrate 6 different light sources with power ranging from 5W to 12W per source. With a weight of around 19.5kg, they are easily transportable.

- Large-scale booths: designed for evaluating bulky samples such as automotive panels, large fabrics, or finished products. They can weigh up to 60kg and offer greater flexibility in sample arrangement.

- Customized configurations: some applications require specific combinations of light sources or particular dimensions, such as “harmony rooms.” Specialized manufacturers provide tailor-made solutions for specific technical needs.

The choice of the most suitable booth depends on several factors: sample type, frequency of use, available laboratory space, and budget.

It is also important to consider ease of maintenance and availability of technical support, factors that affect long-term operating costs.

Standards and reference regulations

The design and use of light booths are regulated by specific international standards that ensure uniformity and reliability in color evaluations.

The main standards include ISO 3664 for visual observation conditions and ASTM D1729 for color evaluation.

For critical automotive applications, the SAE J361 standard defines specific requirements for color tests requiring high precision.

These standards specify key technical parameters:

- Light intensity: illumination levels between 1000 and 3000 lux on the observation surface,

- Lighting uniformity: maximum variations of 20% across the evaluation area,

- Color Rendering Index (CRI): values above 90 to ensure faithful color reproduction,

- Color temperature: specific tolerances for each type of standardized light source.

Compliance with these standards ensures that results are comparable across different laboratories and instruments, an essential element for quality certification and supply chain communication.

Maintenance and monitoring

To maximize the effectiveness of the tool, it is necessary to follow precise operational protocols:

- keep the viewing surface clean,

- replace light sources promptly when necessary,

- regularly calibrate light intensity.

Automatic monitoring of the operating time of each source facilitates preventive maintenance scheduling.

The booth must be kept clean to avoid reflection issues and discrepancies during use.

How to choose a Light Booth

Investing in a professional light booth requires careful evaluation of technical specifications, reference standards, and specific operational needs. The choice must consider not only immediate requirements but also the future evolution of company needs.

The technological evolution towards LED systems has brought significant advantages in terms of energy efficiency, lifespan, and color stability, making these tools increasingly accessible even to medium-sized laboratories that require high-quality standards.

The stability of LED sources also ensures excellent viewing conditions for long-term reliable decisions, reducing operating costs and increasing quality control productivity.

Operator training also represents a fundamental investment to achieve reliable and repeatable results.

Subscribe to newsletter

Ask for a free consultation

Our experts will contact you to show you a demo of our products