11-01-2023

The Colorimeter: precision and Color control in industrial applications

The colorimeter is a fundamental instrument in industrial quality control, designed to measure and quantify color objectively and consistently.

Unlike the subjective perception of the human eye, this precision device provides standardized numerical values that allow companies to maintain consistent color quality throughout the entire production process.

What is a Colorimeter used for?

A colorimeter is used across numerous industrial sectors where color consistency is a critical factor for commercial success. This instrument enables companies to establish precise color standards and verify that each production batch meets the required specifications.

Main applications include:

- Production quality control: verifying color conformity with reference samples,

- Formulation of dyes and paints: developing new shades with mathematical precision,

- Color matching: identifying exact correspondences between different colors,

- Stability monitoring: checking for chromatic variations over time,

- Compliance certification: providing objective documentation for international standards.

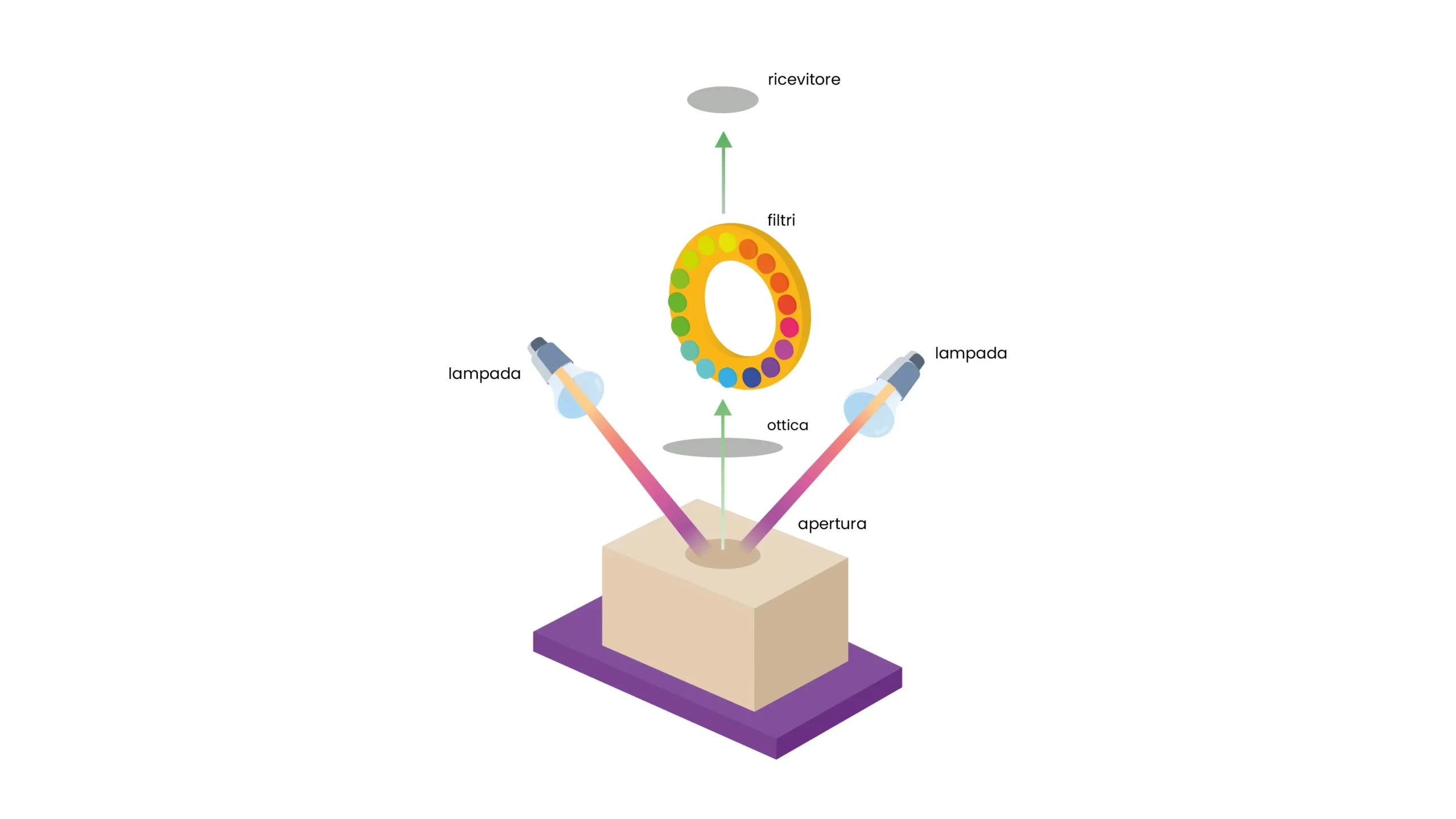

How does a Colorimeter work?

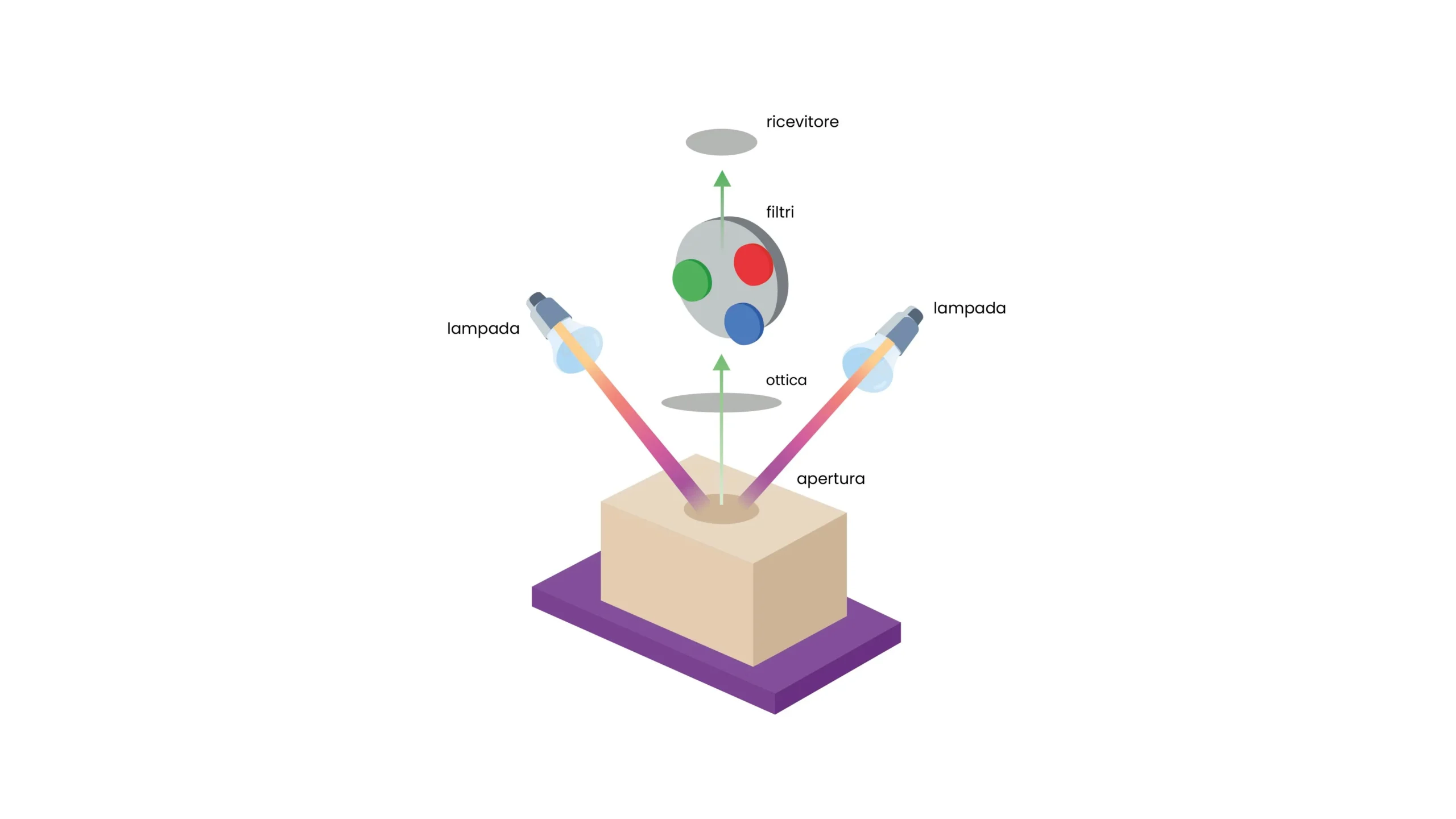

A colorimeter works by measuring the light reflected or transmitted by the materials being analyzed. The device uses specific optical filters that isolate the fundamental components of visible light—red, green, and blue—corresponding to the primary colors perceived by the human eye.

The measurement process includes several sequential steps:

- Sample illumination: a standardized light source uniformly illuminates the material,

- Collection of reflected light: photosensitive sensors capture the light reflected by the sample,

- Optical filtering: specific filters separate the primary color components,

- Conversion to numerical data: the light values are converted into standard colorimetric coordinates,

- Processing results: mathematical algorithms calculate the final color parameters.

How to use a Colorimeter

Proper use of a colorimeter requires standardized procedures to ensure reliable and repeatable results. The process always begins with calibration using certified reference standards.

Standard operating steps include:

- Initial calibration: using certified white and black plates to zero the instrument,

- Sample preparation: cleaning and correctly positioning the material to be analyzed,

- Parameter configuration: selecting the appropriate illuminant and standard observer,

- Measurement execution: precise positioning of the colorimeter on the sample,

- Data recording: saving measured values in the internal database,

- Result interpretation: analyzing colorimetric coordinates and color difference parameters.

Colorimeter Applications in Industrial Sectors

Colorimeters are indispensable tools in many industrial sectors where color consistency and quality are critical for commercial success. Their ability to provide objective and standardized measurements makes them essential for companies operating in highly competitive markets.

Automotive Industry

In the automotive sector, colorimeters ensure chromatic uniformity between components produced in different plants and at different times. Car body painting requires absolute precision to avoid visible differences between panels, doors, and replacement parts.

Textile and Fashion Industry

The textile industry uses colorimeters to control the chromatic consistency of yarns, fabrics, and finished garments. This is especially crucial for brands that must maintain recognizable and uniform color standards across collections and production batches.

Food Industry

In the food industry, color often indicates product quality, freshness, and consistency. Colorimeters help monitor processes such as cooking, ripening, and preservation, ensuring stable quality standards.

Cosmetics Industry

Cosmetics require extreme precision in the formulation of foundations, lipsticks, and makeup products. Colorimeters enable the creation of specific shades and ensure they remain consistent across production batches.

Chemical and Paint Industry

In the chemical and paint industries, the colorimeter is essential for pigment, dye, and coating formulation. The ability to quantify color mathematically allows exact replication of desired formulations.

Pharmaceutical Industry

The pharmaceutical industry uses colorimeters for drug quality control, as color variations may indicate stability issues or degradation of active ingredients.

What Is the difference between a Spectrophotometer and a Colorimeter?

A colorimeter is not the only tool for acquiring and measuring color. Spectrophotometers, although similar, offer significantly higher performance. To understand why, it is necessary to examine how these instruments function.

How a Spectrophotometer works

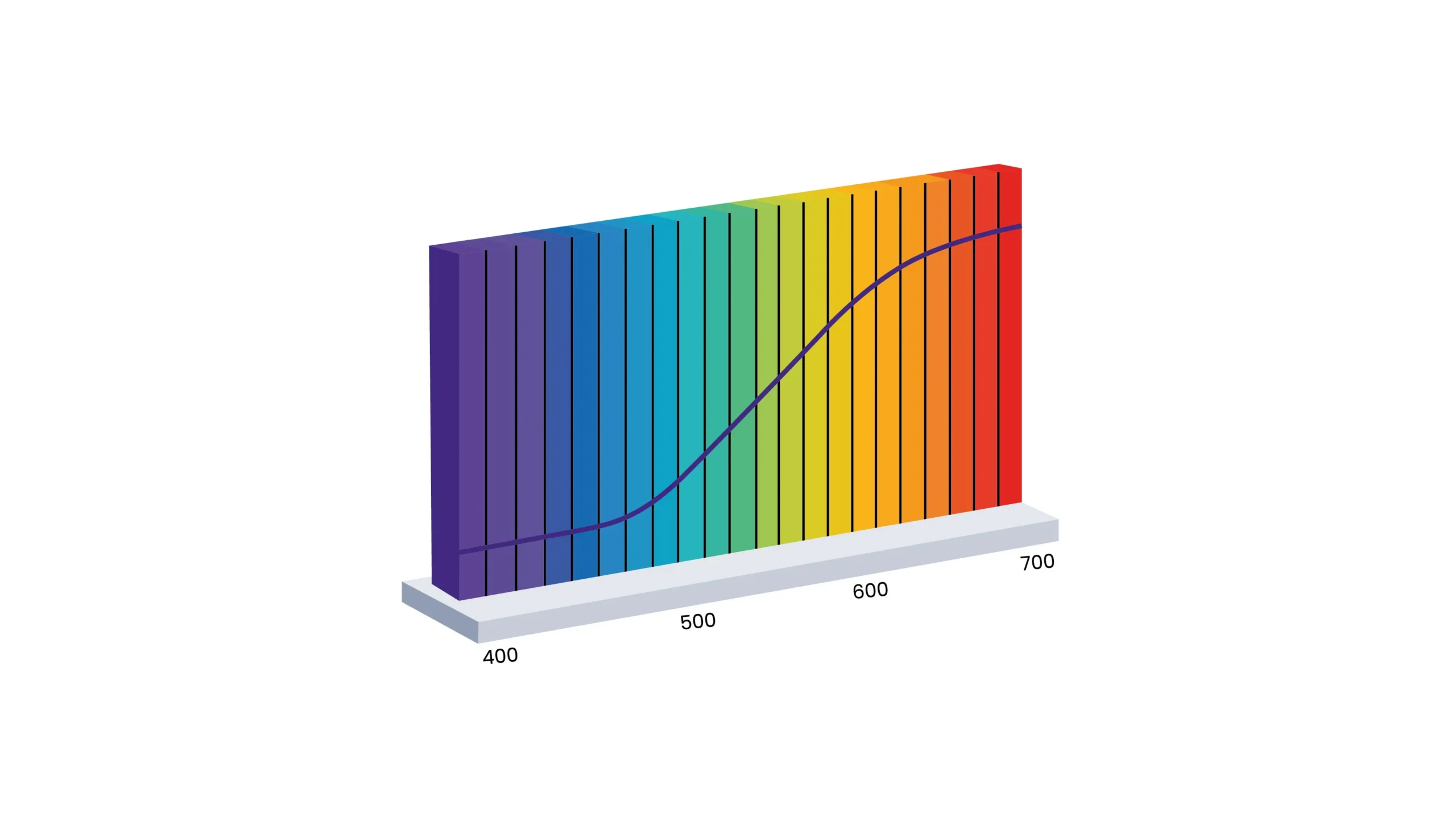

Compared to a colorimeter, a spectrophotometer provides a full analysis of the visible spectrum from 400 to 700 nanometers, typically in 10 nm intervals.

It can operate in two modes:

- Reflection mode: illuminates the sample and measures the reflected light through a probe, which is then decomposed into monochromatic sources between 400 and 700 nm and converted into numerical data

- Transmission mode: measures the light that passes through the sample, decomposing it into monochromatic sources and converting the data for analysis.

How a Colorimeter works

Unlike the spectrophotometer, a colorimeter does not measure individual monochromatic sources within the 400–700 nm range but quantifies only three resulting components—red, green, and blue—representing human color perception.

Why choose a Spectrophotometer over a Colorimeter

The main advantage of a spectrophotometer over a colorimeter lies not only in its broader spectral coverage (400–700 nm, typically measured every 10 nm), but also in its versatility, accuracy, and adaptability to various surfaces and environmental conditions. Spectrophotometers can operate in both reflection and transmission modes, offering more reliable and repeatable results—especially in industrial applications where maximum precision is essential.

For this reason, if you need a high-performance, future-proof device, a spectrophotometer is a better investment than a simple colorimeter.

If you want to learn more or view the available models, you can consult our product lines directly:

Colorimeters can be useful for quick and simple checks, but for professional applications, tight tolerances, and consistent results over time, the spectrophotometer represents the most reliable and durable choice.

Types of Colorimeters: solutions for every need

The market offers several types of colorimeters designed to meet specific operational requirements. Choosing the most suitable model depends on the application, the type of materials to be analyzed, and the required precision level.

Portable Colorimeter

Portable colorimeters are ideal for field measurements or on-site quality control directly on production lines. These compact instruments feature rechargeable batteries and wireless communication systems for data transmission.

Key features include:

- Operational autonomy: extended operation without external power supply,

- Structural robustness: resistance to impact and harsh environmental conditions,

- Ease of use: intuitive interface suitable for non-specialized operators,

- Advanced connectivity: data transfer via Bluetooth or Wi-Fi.

Digital Colorimeter

Next-generation digital colorimeters incorporate advanced technologies for managing and processing color data. These devices offer integrated software functions for statistical analysis and professional report generation.

Paint Colorimeter

Specifically designed for the paint and coatings industry, these colorimeters handle the unique properties of liquid materials and surfaces with varying reflective characteristics. The measurement geometry is optimized for materials with different gloss and texture levels.

FAQ on Colorimeters

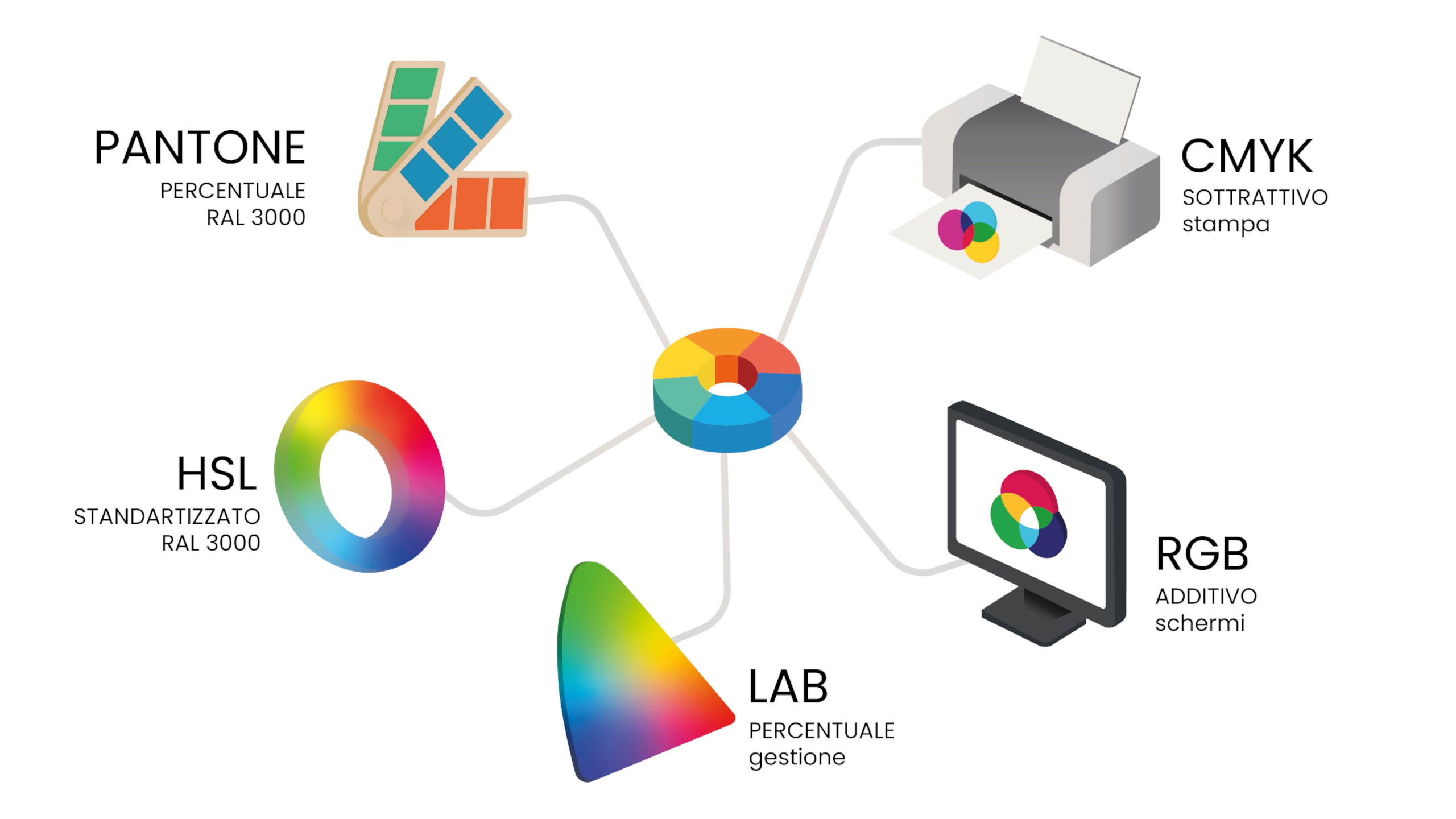

What are the values provided by a Colorimeter?

Colorimeters provide standardized numerical values that mathematically describe the chromatic characteristics of the materials being analyzed. The most commonly used coordinate system is CIE L*a*b*, which represents color through three fundamental parameters.

The main parameters include:

- *L (Lightness)**: a value between 0 (black) and 100 (white) that indicates the lightness of the color.

- *a (Red–Green axis)**: positive values indicate a shift toward red; negative values indicate a shift toward green.

- *b (Yellow–Blue axis)**: positive values indicate a shift toward yellow; negative values indicate a shift toward blue.

- C (Chroma)**: the intensity or saturation of the color, typically calculated as the distance from the L* axis in the a*–b* plane (C* = √(a*² + b*²)).

- h° (Hue angle): the angle that defines the hue of the color within the a*–b* plane.

How to calibrate a monitor without a Colorimeter?

Although professional monitor calibration requires a dedicated colorimeter, there are alternative methods to improve a display’s color rendering when such a tool is not available.

Common techniques include:

- Use of standardized test patterns: reference images that help manually adjust brightness and contrast.

- Calibration software: programs that guide the user through step-by-step parameter adjustments.

- Comparison with physical standards: using certified color samples for visual verification.

- Preset profiles: selecting appropriate color profiles for the type of monitor in use.

However, it is important to emphasize that these methods cannot replace the precision of an instrument-based calibration, which is particularly critical in industrial environments where color fidelity is essential.

What is a Colorimeter in chemistry?

In the chemical-analytical context, the colorimeter serves as an instrument for quantitative analysis of colored solutions. This type of colorimeter—often called a photocolorimeter—uses the correlation between the intensity of a solution’s color and the concentration of the chemical species present.

The operating principle is based on the Beer–Lambert law, which establishes a linear relationship between a solution’s absorbance and the solute concentration. This analytical technique is used for numerous quantitative determinations, from pH measurement to the concentration of metal ions.

What Is ΔE in a Colorimeter?

ΔE (Delta-E) represents the most important parameter for quantifying the color difference between two colors. This numerical value indicates the Euclidean distance in a three-dimensional colorimetric space and provides an objective measure of the visual perception of color difference.

Common interpretation ranges include:

- ΔE < 1: difference not perceptible to the human eye.

- ΔE 1–3: difference perceptible only to expert observers.

- ΔE 3–6: difference clearly visible but acceptable for many applications.

- ΔE 6–12: significant difference that requires correction.

- ΔE > 12: difference unacceptable for professional applications.

There are several formulas for calculating ΔE, with ΔE76, ΔE94, and ΔE2000 among the most widely used standards, each offering different characteristics in terms of correlation with human visual perception.

What is the best Colorimeter?

The optimal colorimeter depends on many factors that should be evaluated in relation to the specific operational needs of the company. There is no single universally superior model; instead, there are solutions better suited to particular applications.

Key selection criteria include:

- Measurement accuracy: repeatability and accuracy of results.

- Range of supported materials: compatibility with different surface types and substrates.

- Ease of use: user interface and operational simplicity.

- Build robustness: resistance to environmental working conditions.

- Software support: analysis and data management functionalities.

- After-sales service: technical support and availability of calibration services.

How much does a Colorimeter cost?

The colorimeter market features a wide range of prices that reflect the different categories of instruments and their relative performance. Price structure typically scales with technological complexity and functionality.

Typical price ranges:

- Entry-level colorimeters (€1,000 – €3,000): basic instruments for simple quality control applications, offering essential features and suitable precision for many standard industrial activities.

- Professional colorimeters (€3,000 – €8,000): mid-range devices with higher performance, advanced software, and greater versatility, ideal for laboratories and research centers.

- High-end colorimeters (€8,000 – €15,000): precision instruments with advanced technologies and comprehensive software features, supporting stricter international standards.

- Integrated systems (€15,000 – €30,000+): complete solutions that include colorimeters, advanced management software, specialized accessories, and certified calibration services.

Economic evaluation should consider not only the initial purchase price but also long-term operational costs, including periodic calibrations, maintenance, and software updates required to maintain optimal performance over time.

Subscribe to newsletter

Ask for a free consultation

Our experts will contact you to show you a demo of our products