14-11-2024

ColorWorkDesk: How to Choose a Spectrophotometer

When it comes to choosing a spectrophotometer, the first step is understanding the specific needs related to its intended use. Instrument type, working methods, and the characteristics of the materials to be analyzed are all variables to consider in the selection process.

In this article:

- Reflection or Transmission? The first criterion for choosing a spectrophotometer

- Instrument Geometries: The best choice for reflection measurement

- Light Behavior and Human Perception

- 45°/0 Instrument Geometry

- d/8° Instrument Geometry and Integrating Sphere

- Measuring Glossy and Matte Materials: Differences between 45°/0 and d/8°

- Multi-Angle Evaluations and Interference Materials

- Portable or Benchtop Spectrophotometers: An Operational Choice

- ColorWorkDesk Spectrophotometers: Innovation in Color Measurement

Reflection or Transmission? The First Criterion for Choosing a Spectrophotometer

One of the fundamental criteria for choosing a spectrophotometer is determined by the type of material to be analyzed: is it transparent or opaque?

The choice between reflection or transmission measurements depends on this aspect.

For more on this topic, refer to the article “ColorWorkDesk: How Spectrophotometers Work.”

In any case, not all spectrophotometers include the capability to measure transmission. In fact, most of them are focused on reflection.

The need to measure either transmission or just reflection, therefore, represents the first criterion for selecting a spectrophotometer.

Light and Object Interaction: How We Perceive the Color of a Material

To understand the second criterion for choosing a spectrophotometer—instrument geometries—it’s essential to briefly review how light interacts with an object when it strikes it.

Light can be reflected, absorbed, or transmitted by the material it hits. The quantity and quality of light reflected, absorbed, or transmitted depend on the material’s optical properties, such as its composition, surface, and thickness.

In colorimetry, these interactions are fundamental as they determine the perceived color of an object.

Instrument geometries, designed to accurately capture and analyze reflected or transmitted light, allow for precise quantification and faithful reproduction of a material’s color by measuring the interaction between light and the material from different, specific angles.

Instrument geometries, therefore, play a crucial role in color measurement, and choosing the right one is essential in colorimetry.

Instrument Geometries: The Best Choice for Reflection Measurement

Leaving aside transmission measurement for now and focusing on reflection measurement, it becomes important to consider the various available instrument geometries—key elements for determining how reflected light is measured from a material.

As previously mentioned, instrument geometries are the second criterion for choosing a spectrophotometer.

Some of these geometries, the most commonly used ones, allow for the separate measurement of external and internal reflection from a material.

The light reflected from a surface has two distinct components: in most cases, a low-intensity one, known as specular (or external) reflection, and an internal one.

Specular reflection is the reflection of a portion of the incoming incident light (usually white), which does not penetrate the material but bounces off the surface at precise angles, similar to a mirror.

This external component does not undergo any manipulation by the material and, therefore, does not affect its color, remaining as simple white light, just as it was when emitted.

However, specular reflection determines the perception of surface glossiness (whether the material is glossy or matte).

The internal reflection, on the other hand, is responsible for generating the material’s color.

Light Behavior and Human Perception

When observing glossy and matte samples, specular reflectance can cause difficulties in perceiving the color, especially when the reflected light strikes the observer’s eye at certain angles, making it challenging to evaluate the color accurately.

Operators solve this problem by tilting the sample to reduce or exclude direct reflection, directing the glare elsewhere.

For matte materials, this issue is not significant, as external light is not reflected directly into the eye but is uniformly diffused in all directions.

45°/0 Instrument Geometry

There are several instrument geometries used for reflection measurement.

One of the most common is the 45°/0 geometry, where light is projected onto the sample at a 45° angle, and the sensor, positioned on the surface, measures the light reflected perpendicularly to the surface.

This eliminates external reflection at the opposite 45°, minimizing the influence of specular reflection and providing results consistent with human color perception.

This geometry is used for flat materials such as inks and printed sheets of paper but becomes less functional for other materials with irregular surfaces.

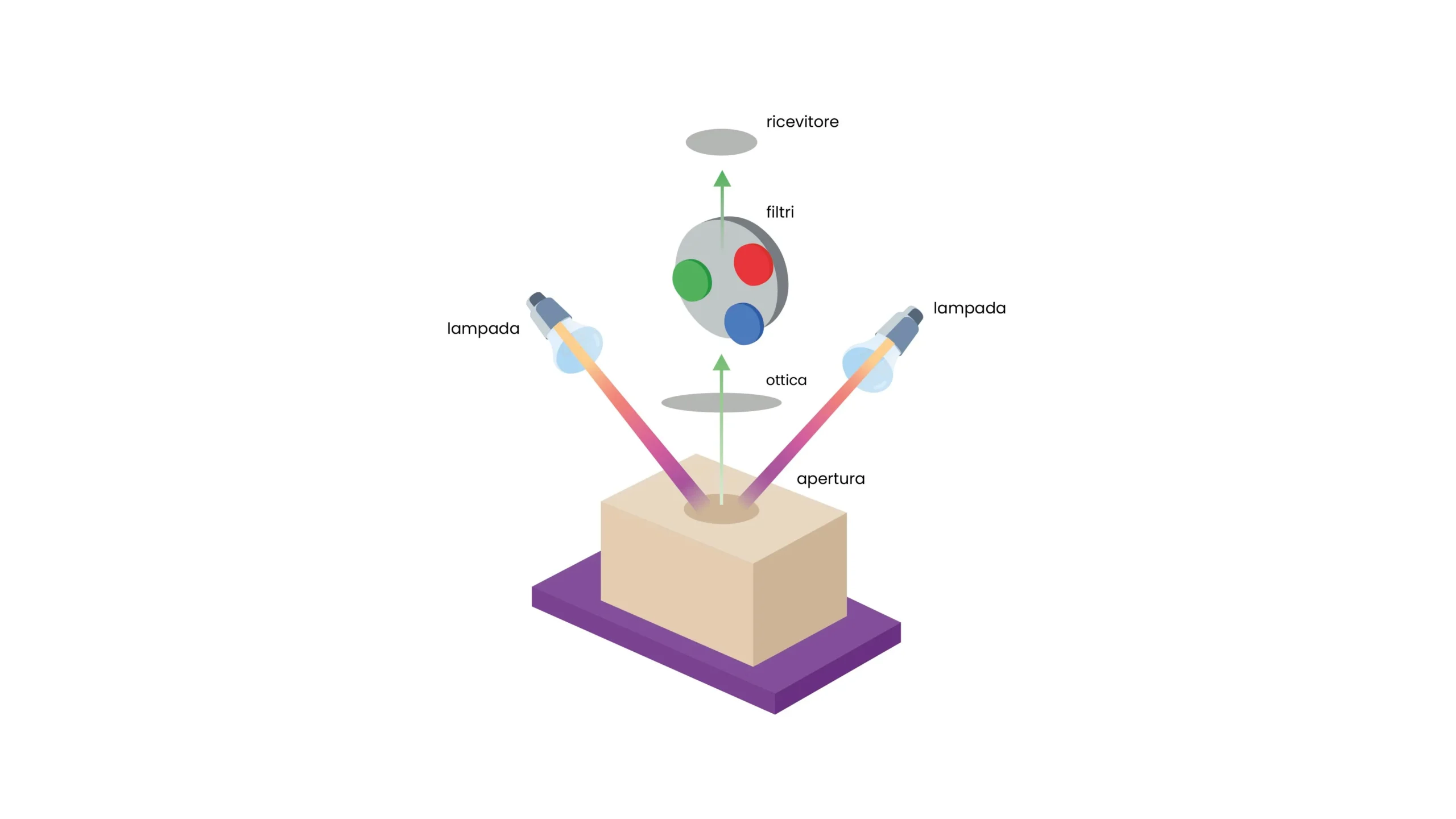

d/8° Instrument Geometry and Integrating Sphere

For materials with irregular surfaces, such as embossed surfaces where external reflection is neither perfect nor predictable, the d/8° instrument geometry is preferred.

To overcome the issue of irregular surfaces, direct light is eliminated by using a lamp that illuminates the inside of an integrating sphere.

This sphere, made of white material, diffuses the light as uniformly as possible around the sample.

As a result, the sample receives light from all directions, and even with an irregular surface, the measurement remains relatively accurate.

The probe, in this case, is positioned at an 8° angle relative to the perpendicular, allowing it to capture both internal and specular reflection.

This is ensured because the diffuse illumination within the sphere covers even the 8° opposite to the light source, recording external reflected light.

This type of geometry measures total reflection (both internal and external), providing a more comprehensive evaluation of the material, even if human perception may differ.

Measuring Glossy and Matte Materials: Differences Between 45°/0 and d/8°

When comparing colors measured with different geometries, even though absolute values may differ, visual results are generally consistent. However, for materials with the same color but differing surface states (glossy or matte), the 45°/0 and d/8° geometries yield different visual results.

The 45°/0 geometry, aligned with human perception, shows matte materials as lighter than glossy ones, while the d/8° geometry shows the opposite, with glossy materials appearing lighter due to specular reflectance.

Although this issue is known, errors can be avoided. Results from both geometries can be reconciled by using the specular reflectance inclusion/exclusion function in the d/8° geometry.

This is achieved by an opening on the sphere opposite the probe that can be closed or opened. When the opening is closed, specular reflection is included; when open, it is excluded, aligning the measurement more closely with the 45°/0 geometry.

Multi-Angle Evaluations and Interference Materials

For non-homogeneous materials like metallic or interference-effect ones, instruments with multiple geometries used simultaneously (multi-angle measurements) are available.

This method allows color to be measured from various angles simultaneously, providing a series of spectra that can be analyzed separately to observe both diffuse and non-diffuse reactions.

Portable or Benchtop Spectrophotometers: An Operational Choice

The final factor in choosing a spectrophotometer is deciding between a portable or benchtop device.

Portable spectrophotometers are better suited for fieldwork and measure only reflection, while benchtop devices offer greater precision for complete lab analyses.

ColorWorkDesk Spectrophotometers: Innovation in Color Measurement

The ColorWorkDesk (CWD) line of portable and benchtop spectrophotometers introduces a new era in colorimetry.

These advanced tools provide precise color evaluations for any material under any conditions, measuring both reflection and transmission.

Their versatility ensures comprehensive and accurate color measurements, making them a standout choice for modern industrial applications.

Subscribe to newsletter

Ask for a free consultation

Our experts will contact you to show you a demo of our products