Metamerism: what It is and how It affects Color Control

In the field of industrial colorimetry, metamerism represents one of ...

Start typing your search key

Benchtop Spectrophotometers represent the ideal solution for color quality control in laboratory and industrial environments. These precision instruments allow for accurate measurement of the chromatic characteristics of various types of samples, ensuring reliable and repeatable results. Designed for use on stable work surfaces, they offer advanced functionality for spectral analysis, color formulation and quality control, representing a strategic investment for companies operating in the paint, plastic, textile, cosmetic and food sectors.

Precision and repeatability in color measurement, color formulation and quality control: this is what the ColorWorkDesk SERIES BSF benchtop spectrophotometers are all about.

THE NEW GENERATION OF

BENCHTOP SPECTROPHOTOMETERS

The CWD BSF SERIES benchtop spectrophotometers belong to the new generation of color measurement instruments with LED/XENON technology, equipped with pre-installed Color Quality Control software.

CHARACTERISTICS

The CWD BSF 100, 200 e 300 models are compact and ergonomic instruments equipped with a sample holder compartment for transmittance, a 7″ TFT touch screen display and an integrated camera for color vision.

USE

The high precision and great reliability of these tools allow the user to analyze, formulate and effectively control the color and appearance of solid products, liquids, pastes, powders, pills and granules in a simplified and guided process.

Benchtop spectrophotometers are advanced analytical instruments designed to accurately measure the optical and chromatic properties of materials. Unlike portable spectrophotometers, these devices are designed for fixed installation on workbenches, offering superior mechanical stability and optimized measurement performance. Their robust structure and studied ergonomics make them perfect for intensive use in quality control laboratories, research centers and production departments where maximum accuracy in color evaluation is required.

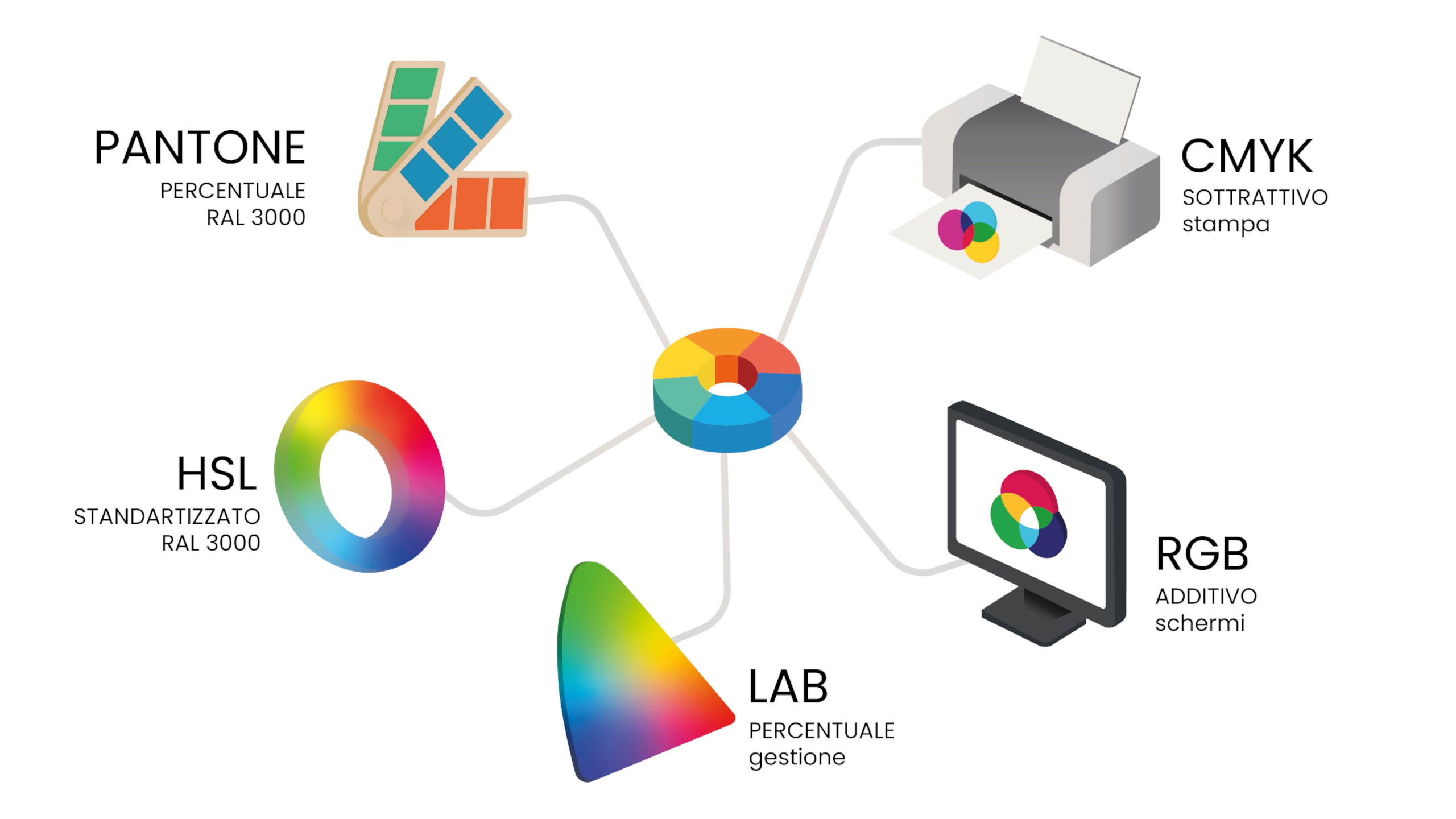

The operating principle is based on illuminating the sample with a controlled spectrum light source (LED or Xenon) and subsequent analysis of reflected or transmitted light through a spectral detection system. The device measures the intensity of light radiation at different wavelengths in the visible spectrum (380-780 nm), generating a unique “spectral signature” of the sample. This data is then processed by integrated software to calculate colorimetric coordinates according to international standards (CIE Lab*, XYZ, RGB) and provide precise and comparable chromatic quality indices.

Benchtop spectrophotometers find application in numerous industrial sectors where color control is crucial for the quality of the final product:

Choosing a benchtop spectrophotometer offers numerous advantages compared to portable alternatives:

When evaluating a benchtop spectrophotometer, it is important to consider some fundamental technical characteristics:

To ensure optimal performance over time, benchtop spectrophotometers require regular maintenance that includes:

Daily calibration with certified white and black standards Periodic cleaning of optics and sample holders Verification of thermal stability and control of environmental conditions Software updates and backups of color databases Periodic metrological checks with traceable reference standards

Investment in a preventive maintenance program ensures the longevity of the instrument and the reliability of measurement results, essential elements for the success of any color quality control system.

Modern benchtop spectrophotometers are designed to integrate seamlessly into industrial workflows through:

Network connectivity for sharing data and chromatic standards Software interfaces compatible with ERP and quality management systems Standardized communication protocols for industrial automation Traceability systems for quality monitoring throughout the entire production chain

This integration allows for optimizing decision-making processes, reducing quality control times and improving business competitiveness through more efficient and accurate color control.

In our blog you will find all the information you need to make the most of and appreciate the benefits of the innovative ColorWorkDesk system.

ALL THE ARTICLES

In the field of industrial colorimetry, metamerism represents one of ...

L’Color Analysis is a scientific discipline that focuses on objectively ...

Color communication represents a fundamental challenge for companies operating in ...

Light booths, also known as illumination booths or color viewing ...

Our experts will contact you to show you a demo of our products

Stai utilizzando un browser obsoleto.

Il seguente sito NON è ottimizzato per Internet Explorer.

A fatal exception IE has occurred at C0DE:L05TUD10 in 0xC0DEBA5E.

oppure clicca il pulsante qui sotto:

aggiorna il tuo browser!